Most people realize that the Cloth Room parameters for density, friction, resistance, damping and so one are essential in discriminating one type of cloth material from another. But what do they mean? What are proper values? Can we insert textbook values, and which textbooks to use? How do they affect the sim process, and the sim result? Which dials to turn, and how much, to accomplish specific effects? And so on. Let’s find out.

But first, let’s consider our limits in this.

- Real cloth either comes as non-woven (leather, fleece, rubber…) or woven.

Non-woven material can have various internal structures. Leather is organic (cells), fleece is long fibers pressed together, rubber is an oil residue (long molecules) and so on.

Woven materials have various internal structures as well. Thread material (cotton, silk, polymer…), thread thickness, weave structure, weave tightness, and so on are discriminating factors. And one can discuss whether knits are special weave structures, or something separate.

For a lot of those elements detailed information seems to be available, but unfortunately not for the ones making up our daily clothes. Special purpose clothing, industrial cloth use, high performance cabling, fire resistance, enhancing tires, and more. Even for regular clothing fibers the most interest is whether spindles of them can keep up with the tensions in a high speed sewing machine. Nothing for our practical Poser use. - Real cloth, especially the woven kind, comes as a mix. For example: cotton threads vertically, but polymer threads added in horizontally for enhanced stretching in that direction. Or for enhanced non-stretching, or for enhanced longevity (anti-wearing). This enhancing really makes a difference. Or thin threads in one direction, thicker threads in the other direction, while being 100% cotton. Cloth is not that homogeneous.

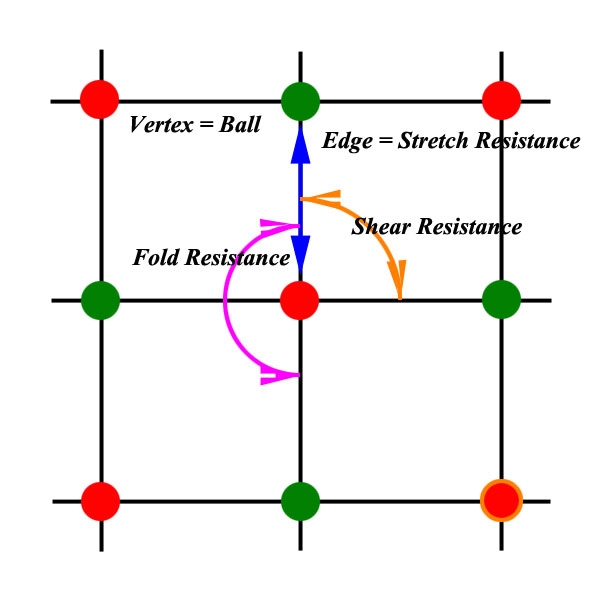

So even if we would know the details of the individual components it would be hard to determine the behavior of the final fabric from that. - Real cloth behavior is translated to a concept that can be understood and described easily using some basic physics laws, like the “spring net” idea of balls, tension and torsion springs. Unfortunately, even simple fibers do not behave completely according to those basic physics laws, and springs are only a limited representation of them. Better representations however are much harder to describe – especially in layman’s terms and in basic physics math. So we, just Poser users, have a choice between a decent understanding of a bad representation, and a bad understanding of a decent representation. Of course we like the decent understanding, while Poser likes the decent result. So even already before any software supplier has got involved, the gap between user and software has become unbridgeable. It’s not your fault, it’s not their fold, we all just want good results fast in a well understood way without the need of a real PhD in cloth physics.

- That (spring net) concept is translated again, into a computer simulation. This is a world on its own, with finite elements instead of the infinitesimal small elements in nature. With shortcuts to save time and resources. With artifacts in the solutions because their worlds have boundaries, finite sizes, and the algorithms don’t converge to the last digit.

- And then, Poser comes with a 3D mesh (OBJ). Should it be taken into account? Should vertex density, polygon size, edge length and direction be given some meaning?

So, the cloth behavior describing parameters can be loaded with real world numbers. But a lot of them will hardly be available for real world every day clothing, from lace lingerie to plated armor outfit, from fur coat to suits, shirts and jeans. And if we use those numbers anyway, the parameters might hamper the simulation itself to get a decent result in due time. And their effects might change on various mesh structures. Hence, real world values are a good point to start. Then we might find a need for adjustments.

In the meantime all this is not about theory. This is us discovering Cloth Room. It’s not Virtual, it’s Reality. For me this implies that when I get weird results, it’s either in the simulation algorithm, or in my interpretation of reality. I do need a proper understanding of real life cloth, to bring Cloth Room to life.